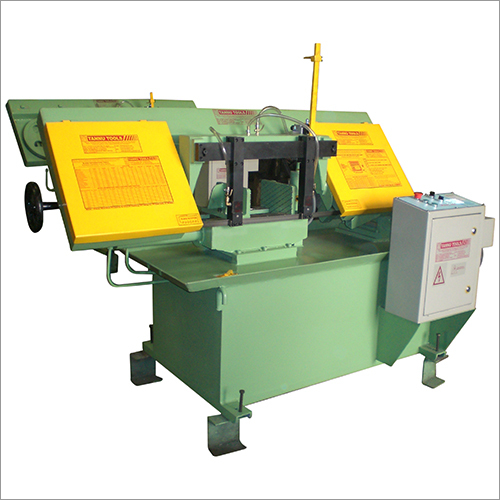

Semi Automatic Bandsaw Machine

MOQ : 1 Unit

Semi Automatic Bandsaw Machine Specification

- Drive Motor

- Induction Motor

- Product Type

- Semi-Automatic Bandsaw Machine

- General Use

- Industrial Metal Cutting

- Material

- Mild Steel

- Type

- Horizontal Bandsaw

- Capacity

- Max Cutting Diameter 260 mm

- Weight (kg)

- Approx. 650 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Cutting Speed

- Variable 20-120 m/min

- Cutting Thickness

- Up to 260 mm

- Cutting Function

- Semi-Automatic

- Cooling System

- Integrated coolant pump

- Drive Type

- Hydraulic

- Voltage

- 415 V

- Dimension (L*W*H)

- 1800 mm x 950 mm x 1200 mm

- Feature

- Heavy-duty construction, High cutting accuracy, and robust design

- Color

- Industrial Blue and Yellow

- Motor

- 2 HP, 3 Phase

- Mechanical Precision

- 0.05 mm

- Software Detail

- Manual Operation, No software required

- Cutting Method

- Continuous band saw cutting

- Control System

- Manual/Panel Controlled

- Cutting Area

- 260 mm x 260 mm

- Cutting Material

- MS, SS, Aluminium, Brass

- Feed System

- Hydraulic feed control

- Suitable Workpiece Shape

- Bar, pipe, solid and hollow sections

- Lubrication System

- Automatic Lubrication

- Blade Size

- 3500 mm x 27 mm x 0.9 mm

- Minimum Cutting Diameter

- 12 mm

- Safety Features

- Emergency stop, Cover interlock

- Blade Guides

- Carbide and bearing type

- Frame Construction

- Fabricated steel frame for vibration-free cutting

- Vice Type

- Hydraulic clamping mechanism

- Blade Tension Adjustment

- Manual hand wheel

- Noise Level

- Below 80 dB

- Maximum Cutting Length

- Unlimited with material support

- Coolant Tank Capacity

- 50 Liters

- Power Consumption

- 2.5 kW

- Dust Extraction

- Provision available

Semi Automatic Bandsaw Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Packaging Details

- As per requirement

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008

About Semi Automatic Bandsaw Machine

SWING TYPE SEMI AUTOMATIC MACHINE MODEL HSA 350

- Well Design Band Saw Machine for trouble free and Higher Production.

- High Efficiency Gear Box.

- Double Acting Hydraulic Cylinder for main vice.

- Step Pulley with V-Belts.

- Infinitely Variable Feed Control Valve for setting the cutting rate.

- Adjustable Heavy Duty Movable Blade Guide.

- Well Equipped Electrical Control Panel.

- Well Equipped Hydraulic Power Pack.

- Automatic Machine off in case of Power Cut.

- Rolling Conveyor (7 feet )

Technical Data of Machine:

Machine Dimension

| Length | 2300 MM |

| Width | 1250 MM |

| Height | 1600 MM |

Machine Electrical Equipment

| Supply Voltage | ~3 x 415V, 50Hz, TN-C-S |

| Protection Degree | IP 54 |

Driving Engine of the Band Saw

| Type | ~3 x 415V, 50Hz |

| Out Put | 2 HP |

Hydraulic and Coolant Motor

| Hydraulic Motor | 1 HP |

| Coolant Pump | 0.25 Hp |

Saw Band Dimension

4850(Length) MM X 34 (Width) MM X 1.1(Thickness) MM

Cutting Capacity

| ROUND SOLID | ROUND HOLLOW | SQUARE/FLAT | HEX SECTION |

| 350 MM | 350 MM | 350 MM X 350 MM | 350 MM |

Robust Frame and Hydraulic Mechanisms

Featuring a fabricated steel frame, this semi-automatic bandsaw offers maximum durability and consistent performance. The hydraulic clamping and feed systems simplify material handling and ensure smooth cuts, reducing manual intervention while maintaining operator safety through integrated emergency and interlock systems.

Precision Engineering and Versatile Cutting

Designed for accuracy and flexibility, the machine uses carbide and bearing blade guides, supporting variable speeds suitable for mild steel, stainless steel, aluminium, and brass. The combination of an automatic lubrication system, manual blade tension adjustment, and dedicated dust extraction provision ensures reliable operation and minimal maintenance.

Industrial-Grade Features for Heavy-Duty Use

Ideal for professional environments, the bandsaw can handle continuous operations on bars, pipes, solid and hollow sections. The integrated 50-liter coolant tank, large 260 mm x 260 mm cutting area, and an approximate 650 kg frame make this machine fit for demanding industrial tasks, delivering exceptional repeatable results without requiring specialized software.

FAQs of Semi Automatic Bandsaw Machine:

Q: How does the semi-automatic bandsaw machine ensure vibration-free cutting?

A: The machines frame is constructed from fabricated steel, which provides exceptional stability and minimizes vibrations during operation. Additionally, the robust design and heavy weight (approx. 650 kg) contribute to maintaining cutting precision even when processing tough materials.Q: What types and shapes of workpieces can be processed with this bandsaw?

A: This bandsaw is suitable for cutting a wide variety of workpieces, including round bars, pipes, solid sections, and hollow sections. It can handle materials such as mild steel, stainless steel, aluminium, and brass, with a maximum cutting diameter of 260 mm and unlimited cutting length, given proper material support.Q: Where and when is the best use for this bandsaw machine?

A: The semi-automatic bandsaw is ideal for industrial and manufacturing environments where precise, heavy-duty metal cutting is essential. Its best used in workshops, fabrication units, and production floors for continuous or batch processing across various shapes and materials.Q: What is the process for operating and maintaining the bandsaw machine?

A: Operation involves manual or panel controls, hydraulic vice and feed system adjustment, and manual blade tensioning via a hand wheel. Maintenance is streamlined with automatic lubrication and an integrated coolant system, while basic safety checks like emergency stop functionality and cover interlock should be regularly verified.Q: How does the hydraulic clamping mechanism benefit the user?

A: The hydraulic clamping vice offers fast, secure setup of different workpieces, ensuring safer and more consistent cuts. This reduces the risk of workpiece movement during cutting and improves overall productivity by minimizing setup time.Q: What safety features are included in the bandsaw machine?

A: Safety is prioritized with features such as an emergency stop button and a cover interlock that prevents the machine from operating unless covers are securely closed, reducing risk of accidental injuries during operation or maintenance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Swing Type Semi Automatic Band Saw Machine Category

Vertical Bandsaw Machine

Minimum Order Quantity : 1 Piece

Automatic : Yes

Warranty : 1 Year

Computerized : No

Drive Type : Electric

General Use : Industrial

Send Inquiry

Send Inquiry