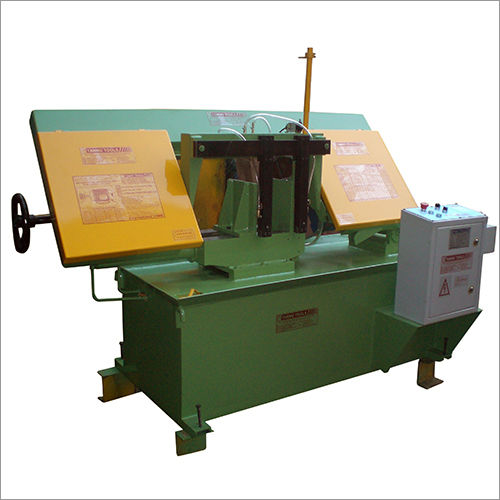

Semi Automatic Bandsaw Machine

Semi Automatic Bandsaw Machine Specification

- Drive Motor

- Heavy Duty Induction Motor

- Product Type

- Metal Cutting Machine

- General Use

- For precise cutting of metal bars, pipes, profiles

- Material

- Mild Steel, Alloy Steel, Stainless Steel

- Type

- Horizontal Bandsaw

- Capacity

- Up to 230 mm (Round); Up to 300 mm (Square)

- Weight (kg)

- Approx. 420 kg

- Computerized

- No

- Automatic

- Semi Automatic

- Cutting Speed

- 20-80 m/min (Variable)

- Cutting Thickness

- Up to 230 mm

- Cutting Function

- Semi Automatic

- Cooling System

- Integrated coolant pump system

- Drive Type

- Electric motor driven

- Voltage

- 415 V / 3 Phase

- Dimension (L*W*H)

- 1900 x 900 x 1200 mm

- Feature

- Rugged construction, High cutting efficiency, Low maintenance

- Color

- Industrial Blue & Grey

- Motor

- 2 HP / 1440 RPM

- Mechanical Precision

- 0.1 mm

- Software Detail

- Not Applicable (Mechanical Operation)

- Cutting Method

- Bandsaw blade

- Control System

- Semi Automatic control system

- Cutting Material

- Ferrous & Non-Ferrous Metals

- Cutting Area

- 230 x 300 mm

- Saw Blade Tension

- Manual adjustment

- Coolant Tank Capacity

- 30 Litres

- Noise Level

- <78 dB

- Blade Guide

- Carbide and roller guides

- Surface Finish

- Powder coated

- Frame Structure

- Heavy-duty welded steel

- Material Feed

- Manual / Hydraulic

- Blade Motor Protection

- Thermal overload relay

- Vice Type

- Manual, Quick clamp

- Hydraulic System

- Integrated for vice clamping and feeding

- Cutting Angle

- 90° (Straight cut)

- Safety Features

- Blade cover, Emergency stop switch

Semi Automatic Bandsaw Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Packaging Details

- As per requirement

- Main Export Market(s)

- Middle East, Western Europe, Africa, Central America, Eastern Europe, Australia, South America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008

About Semi Automatic Bandsaw Machine

SEMI AUTOMATIC BAND SAW MACHINE MODEL HSA 450(DC)

Double Column Based Semi Automatic Band Saw Machine with standard equipment and standard accessories

- Well Design Band Saw Machine for trouble free & Higher Production.

- High Efficiency Gear Box.

- Double Acting Hydraulic Cylinder for main vice.

- Step Pulley with V-Belts.

- Infinitely Variable Feed Control Valve for setting the cutting rate.

- Adjustable Heavy Duty Movable Blade Guide.

- Well Equipped Electrical Control Panel

- Well Equipped Hydraulic Power Pack.

- Automatic Machine off in case of Power Cut.

- Rolling Conveyor (7 feet)

Technical Data of Machine:

Machine Dimension

| Length | 2500 MM |

| Width | 1250 MM |

| Height | 1700 MM |

Machine Electrical Equipment

| Supply Voltage | ~3 X 415V, 50Hz, TN-C-S |

| Protection Degree | IP 54 |

Driving Engine of the Band Saw

| Type | ~3 X 415V, 5oHz |

| Out Put | 5 HP |

Hydraulic and Coolant Motor

| Hydraulic Motor | 1 HP |

| Coolant Pump | 0.25 HP |

Saw Band Dimension

5000 (Length) MM X 34 (Width) MM X 1.1 (Thickness) MM

Cutting Capacity

| ROUND SOLID | ROUND HOLLOW | SQUARE / FLAT | HEX SECTION |

| 450 MM | 450 MM | 450 MM X 450 MM | 450 MM |

Robust Construction for Enhanced Durability

Designed with a heavy-duty welded steel frame and powder-coated finish, this semi-automatic bandsaw machine withstands intensive use in manufacturing and fabrication workshops. Its robust architecture ensures stable cutting, minimizes vibration, and extends the machine life even under rigorous, continuous operation.

Efficient and Safe Cutting Operations

Integrated hydraulic systems offer superior control for vice clamping and material feeding, while the thermal overload relay safeguards the blade motor. User safety is prioritized through a combination of blade covers and an emergency stop switch. These features help maintain safe and efficient working conditions.

Versatile and Precise Metal Cutting

With its adjustable cutting speed (2080 m/min) and support for various metals including mild steel, alloy steel, and stainless steel, this machine delivers consistent precision (0.1 mm) across diverse applications. The 230 x 300 mm cutting area makes it suitable for both round and square metal workpieces.

FAQs of Semi Automatic Bandsaw Machine:

Q: How is the blade tension adjusted on this semi automatic bandsaw?

A: The saw blade tension is adjusted manually using the dedicated tension adjustment mechanism. This allows operators to set optimal tension for various blade types and material thicknesses, ensuring reliable and precise cuts.Q: What safety features does the bandsaw machine include during operation?

A: The bandsaw machine is equipped with a blade cover and an emergency stop switch. These safeguards help prevent accidental contact with moving parts and allow immediate machine shutdown in case of emergencies, enhancing operator safety.Q: When should operators use the manual versus hydraulic material feed?

A: The machine provides both manual and hydraulic material feed options. Manual feeding is ideal for smaller or more delicate workpieces, while hydraulic feed should be used for heavier or repetitive cutting tasks to ensure steady and uniform advancement of materials.Q: Where is this semi automatic bandsaw most commonly used?

A: This machine is primarily used in metal fabrication shops, factories, machine building units, and service centers. Its ability to handle a variety of metals makes it suitable for industries requiring precise, efficient bar and profile cutting.Q: What is the process for clamping materials before cutting?

A: Material is secured using the manual quick-clamp vice, which is further reinforced by an integrated hydraulic vice clamping system. This two-step process guarantees that the workpiece remains firmly held during the entire cutting cycle, resulting in accurate cuts.Q: What benefits does the integrated cooling system provide?

A: The integrated coolant pump and 30-litre tank ensure effective blade lubrication and cooling during prolonged operations. This system reduces blade wear, enhances cutting efficiency, and helps maintain a smooth surface finish on cut materials.Q: How does this bandsaw achieve precise and consistent cuts across different materials?

A: Precision is achieved through the machines rigid frame construction, carbide and roller blade guides, and mechanical accuracy of 0.1 mm. Variable speed control and a stable induction motor further contribute to uniform and high-quality cuts for both ferrous and non-ferrous metals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Double Column Semi Automatic Band Saw Machine Category

Double Column Horizontal Band Saw Machine

Minimum Order Quantity : 1 Piece

Computerized : No

Feature : Automatic Feeding, Good Quality

Warranty : 1 Year

Material : Steel

Drive Type : Electric

Swing Type Band Saw Machine

Minimum Order Quantity : 1 Unit

Computerized : No

Feature : Automatic Feeding

Warranty : 1 Year

Material : Other, Mild Steel

Drive Type : Electric

Semi Automatic Band Saw Machine

Minimum Order Quantity : 1 Piece

Computerized : No

Feature : Automatic Feeding, Good Quality

Warranty : 1 Year

Material : Other, Mild Steel

Drive Type : Electric

Semi Automatic Double Column Bandsaws

Minimum Order Quantity : 1 Piece

Computerized : No

Feature : Automatic Feeding, Good Quality

Warranty : 1 Year

Material : Other, Mild Steel

Drive Type : Electric

Send Inquiry

Send Inquiry